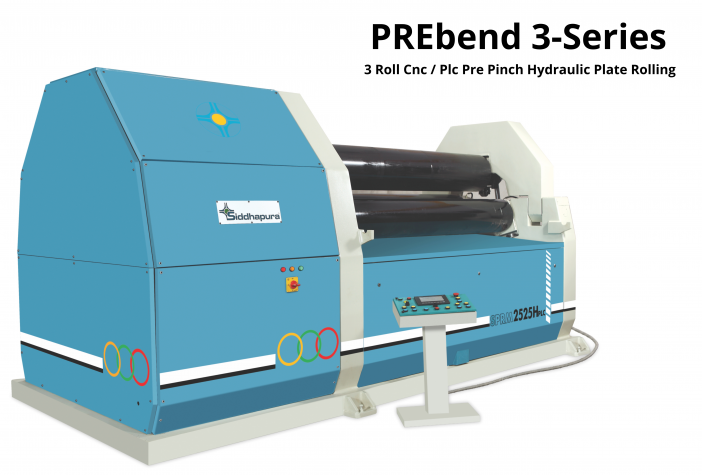

- The machine based on The Pinch Cum Pyramid Principle combine the advantages of 3 Roll & 4 Roll Pyramid type, 4 Roll initial pinch type machine

- Automatic Easy & Instant squaring of the plate alignment using one of the side rolls as a stopper (serves as a real hydraulic back-gauge).

- Easiest machine to operate since material is clamped during the squaring process and held during the entire rolling process.

- Plate is always hydraulically pinched in between the 2 rolls, thus providing constant and nears perfect positioning Excellent degree of pre bending can be achieved with automatic minimization of the flat end width remains.

- Very high degree of process automation and minimum use of cranes, etc. thanks to permanent clamping of the workpiece between top roll and bottom roll.

- Easy plate and precise edge handling allows for work please tack welding on the machine.

- Able to pre-bend, roll and post bend the entire piece without releasing the pinch, allowing some parts to be pre-bend and the entire shell could be finished in single pass only, including pre-bending of both edges. One only side roll position, one only automatic squaring, and no plate handling required at all.

- Material if feed into the machine parallel to the floor, easily fitted with feed tables and side supports, or placed into a pit for ease of operation

- Less floor space is required because the part is rolled up and over right after the first pre-bend.

- Very good calibrating capability for apple or pear shaped work pieces.

- Precise controls with superb quality and appearance.

- Wrapped around while pressed against the top roll, on a longer plate section than on the linear guides, reducing the natural material spring-back (re-opening) effect. Much smaller diameter shells & cones are achievable.

- Independent & Ergonomic designed Mobile Control Operating Console with 7″Colour Touch Screen HMI & Joysticks

Control for whole machine quick functions. - 8 Axis Controller with EASY-bend basic dedicated programming & Advanced Digital Technology (online technical support in real time connecting with SIDDHAPURA Tele Customer Service).

- SMART pro Auto Cycle Programming is available upon request on chargeable base.

- Manual/Auto Programming facility.

- Program save memory capacity 200 (depend on data in our basic version & it’s also expandable)

- Delta Indicator & Tower Light Indicator to display machine functionally operation status.

- Digital Colour Graphically Display of Bar Graph for Side Rolls & Bottom Roll Position & Feeding Position in micron.

- Siemens/ABB / Crompton Electric Motor

- Double Pre Pinch Hydraulically

- The specification of SIDDHAPURA Rolling Machines are harmonious to CE norms & it designed with 2D/3D programs and all calculations are carefully checked with analyzing programs by experienced high skilled engineers before productions are started. All necessary electrical and hydraulic safety precautions are taken by SIDDHAPURA Technical Staff.

Available

Length – 1600 to 6100 mm | Rolling Capacity – 6 to 175 mm | Pre Bending Capacity – 4 to 156 mm

Previous

Next